THE SONOCHEMISTRY CENTRE AT COVENTRY UNIVERSITY

‘The Home of Sound Science’

INTRODUCTION to SONOCHEMISTRY

1. ULTRASOUND

1.1 HISTORICAL BACKGROUND

1.2 THE POWER OF SOUND

1.3 REFERENCES

2. ACOUSTIC CAVITATION

2.1 HOMOGENEOUS LIQUID-PHASE REACTIONS

2.2 CAVITATION NEAR A SURFACE

2.3 HETEROGENEOUS POWDER-LIQUID REACTIONS

2.4 REFERENCES FOR CAVITATION

3.

TRANSDUCERS

3.1

GAS-DRIVEN TRANSDUCERS

3.2

LIQUID-DRIVEN TRANSDUCERS

3.3

ELECTROMECHANICAL TRANSDUCERS

3.3.1

Magnetostrictive Transducers

3.3.2

Piezoelectric Transducers

4. REACTOR DESIGN AND SCALE UP

4.1 Batch Treatment

4.2

Flow Systems

4.3 References

5. EXAMPLES OF RESEARCH

PROJECTS

1. ULTRASOUND

If you were asked what you knew about ultrasound you would almost certainly

start with the fact that it is used in animal communications (e.g. bat

navigation and dog whistles). You might then recall that ultrasound is used in

medicine for foetal imaging, in underwater range finding (SONAR) or in the

non-destructive testing of metals for flaws. A chemist would probably not

consider sound as the type of energy that could be used for the excitation of a

chemical reaction. Indeed up to a few years ago the use of ultrasound in

chemistry was something of a curiosity and the practising chemist could have

been forgiven for not having met the concept. To increase chemical reactivity

one would probably turn towards heat, pressure, light or the use of a catalyst.

And yet, if one stops for a second to consider what is involved in the

transmission of a sound wave through a medium it is perhaps surprising that for

so many years sound was not considered as a potential source of enhancement of

chemical reactivity. The only exception to this being the green-fingered chemist

who, in the privacy of his own laboratory, talks, sings or even shouts at his

reaction. After all, sound is transmitted through a medium as a pressure wave

and the mere act of transmission must cause some excitation in the medium in the

form of enhanced molecular motion. However, as we will see later, in order to

produce real effects the sound energy must be generated within the liquid

itself. This is because the transfer of sound energy from the air into a liquid

is not an efficient process.

1.1 HISTORICAL BACKGROUND

The basis for the present-day generation of ultrasound was established as far

back as 1880 with the discovery of the piezoelectric effect by the Curies [l-3].

Most modern ultrasonic devices rely on transducers (energy converters) which are

composed of piezoelectric material. Such materials respond to the application of

an electrical potential across opposite faces with a small change in dimension.

This is the inverse of the piezoelectric effect. If the potential is alternated

at high frequencies the crystal converts the electrical energy to mechanical

vibration (sound) energy – rather like a loudspeaker. At sufficiently high

alternating potential high frequency sound (ultrasound) will be generated.

The earliest form of an ultrasonic transducer was a whistle developed by Francis

Galton (1822-1911) in 1883 to investigate the threshold frequency of human

hearing [4]. A diagram of the whistle is to be found in the section on

transducers. Galton himself was a remarkable man. As well as inventing the

whistle that carries his name he explored and helped map a portion of the

African interior, invented the weather map and developed the first workable

system for classifying and identifying fingerprints. His whistle was part of his

study of sensory perception, in this case to determine the limits of hearing in

terms of sound frequencies in both humans and animals.

The first commercial application of ultrasonics appeared around 1917 and was the

first “echo-sounder” invented and developed by Paul Langévin (1872-1946). He was

born in Paris and was a contemporary to Marie Curie, Albert Einstein and Hendrik

Lorentz. He was noted for his work on the molecular structure of gases, analysis

of secondary emission of X-rays from metals exposed to radiation and for his

theory of magnetism. However Langévin is more generally remembered for important

work on piezoelectricity and on piezoceramics. The original “echo-sounder”

eventually became underwater SONAR for submarine detection during World War 2.

The transducer was a mosaic of thin quartz crystals glued between two steel

plates (the composite having a resonant frequency of about 50 kHz), mounted in a

housing suitable for submersion. The early "echo sounder" simply sent a pulse of

ultrasound from the keel of a boat to the bottom of the sea from which it was

reflected back to a detector also on the keel. For sound waves, since the

distance traveled through a medium = 1/2 x time x velocity (and the velocity of

sound in seawater is accurately known) the distance to the bottom could be

gauged from the time taken for the signal to return to the boat. If some foreign

object (e.g. a submarine) were to come between the boat and the bottom of the

seabed an echo would be produced from this in advance of the bottom echo. In the

UK this system was very important to the Allied Submarine Detection

Investigation Committee during the war and became popularly known by the acronym

ASDIC. Later developments resulted in a change in the name of the system to

SONAR (SOund Navigation And Ranging) which allowed

the surrounding sea to be scanned. The original ASDIC system predated the

corresponding RAdio Detection And Ranging system

(RADAR) by 30 years.

Essentially all imaging from medical ultrasound to non-destructive testing

relies upon the same pulse-echo type of approach but with considerably refined

electronic hardware. The refinements enable the equipment not only to detect

reflections of the sound wave from the hard, metallic surface of a submarine in

water but also much more subtle changes in the media through which sound passes

(e.g. those between different tissue structures in the body). It is high

frequency ultrasound (in the range 2 to 10 MHz) which is used primarily in this

type of application because by using these much shorter wavelengths it is

possible to detect much smaller areas of phase change i.e. give better

'definition'. The chemical applications of high frequency ultrasound are

concerned essentially with measurements of either the velocity of sound through

a medium or the degree to which the sound is absorbed as it passes through it.

These applications will be discussed in more detail in. Such measurements are

diagnostic in nature and do not effect the chemistry of the system under study.

When more powerful ultrasound at a lower frequency is applied to a system it is

possible to produce chemical changes as a result of acoustically generated

cavitation. Cavitation as a phenomenon was first identified and reported in 1895

by Sir John Thornycroft and Sidney Barnaby [5]. This discovery was the result of

investigations into the inexplicably poor performance of a newly built destroyer

HMS Daring. Her top speed was well below specifications and the problem was

traced to the propeller blades that were incorrectly set and therefore not

generating sufficient thrust. The rapid motion of the blades through water was

found to tear the water structure apart by virtue of simply mechanical action.

The result of this was the production of what are now called cavitation bubbles.

The solution to this problem lies in using very wide blades covering about

two-thirds of the disc area of the propeller, so as to present a very large

surface contact with the water. This helps to prevent disruption under the force

necessary to propel the vessel. As ship speeds increased, however, this became a

serious concern and the Royal Navy commissioned Lord Rayleigh to investigate. He

produced a seminal work in the field of cavitation which confirmed that the

effects were due to the enormous turbulence, heat, and pressure produced when

cavitation bubbles imploded on or near to the propeller surface [6]. In the same

work, he also observed that cavitation and bubble collapse was also the origin

of the noise made when water is heated towards boiling point.

Since l945 an increasing understanding of the phenomenon of cavitation has

developed coupled with significant developments in electronic circuitry and

transducer design (i.e. devices which convert electrical to mechanical signals

and vice versa). As a result of this there has been a rapid expansion in the

application of power ultrasound to chemical processes, a subject which has

become known as “Sonochemistry”.

1.2 T HE

POWER OF SOUND

HE

POWER OF SOUND

Sound,

as a general subject for study, is traditionally found in a physics syllabus but

it is not a topic which is met in a chemistry course and so is somewhat

unfamiliar to practising

chemists. Sound is transmitted through a medium by inducing vibrational motion

of the molecules through which it is travelling. This

motion can be visualised as rather like the ripples produced when a pebble is

dropped into a pool of still water. The waves move but the water molecules which

constitute the wave revert to their normal positions after the wave has passed.

An alternative representation is provided

by the effect of a sudden twitch of the end of a horizontal stretched spring.

Here the vibrational energy is transmitted through the spring as a compression

wave which is seen to traverse its whole length. This is just a single

compression wave and it does not equate to sound itself which

is a whole series of such compression waves separated by rarefaction

(stretching) waves in between. The pitch (or note) of the sound produced by this

series of waves depends upon their frequency i.e. the number of waves which pass

a fixed point in unit time. For middle C this is 256 per second. In physics

sound waves are often shown as a series of vertical lines or shaded colour where

line separation or colour depth represent intensity, or as a sine wave where

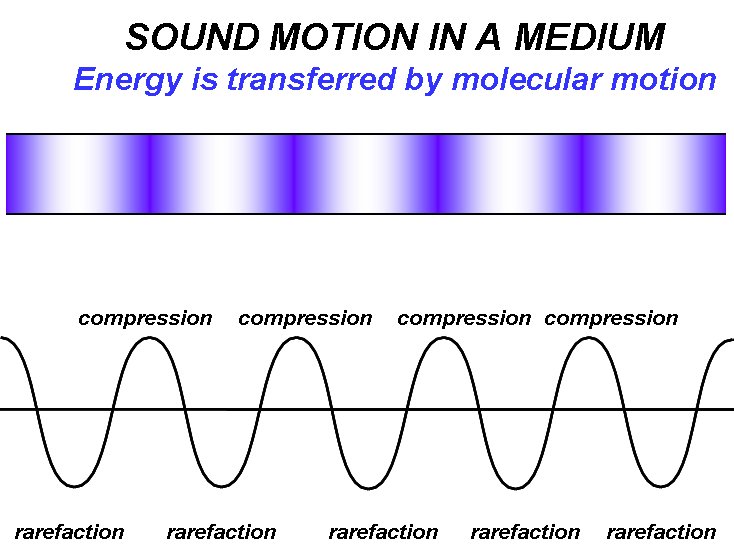

intensity is shown by the amplitude (Figure 1.1).

Figure

1.1: Sound transmission

through a medium

The physical effects of sound vibrations are most easily experienced by standing

in front of a loudspeaker playing music at high volume. The actual sound

vibrations are transmitted through the air and are not only audible but can also

be sensed by the body through the skin. The bass notes are felt through the body

more easily than the high notes and this is connected with the frequency of the

pressure pulse creating the sound. Low frequency sound becomes audible at around

18Hz (1Hz = 1 Hertz = 1 cycle per second) but as the frequency of the sound is

raised (becoming more treble) it becomes more difficult for the body to respond

and that sensation is lost. High frequency sound, while not noticeably effecting

the body does cause severe annoyance to hearing e.g. feed back noise from a

microphone through a loud speaker. At even higher frequencies the ear finds it

difficult to respond and eventually the human hearing threshold is reached,

normally around 18-20kHz for adults, sound beyond this limit is inaudible and is

defined as ultrasound. The hearing threshold is not the same for other animal

species thus dogs respond to ultrasonic whistles (so called "silent" dog

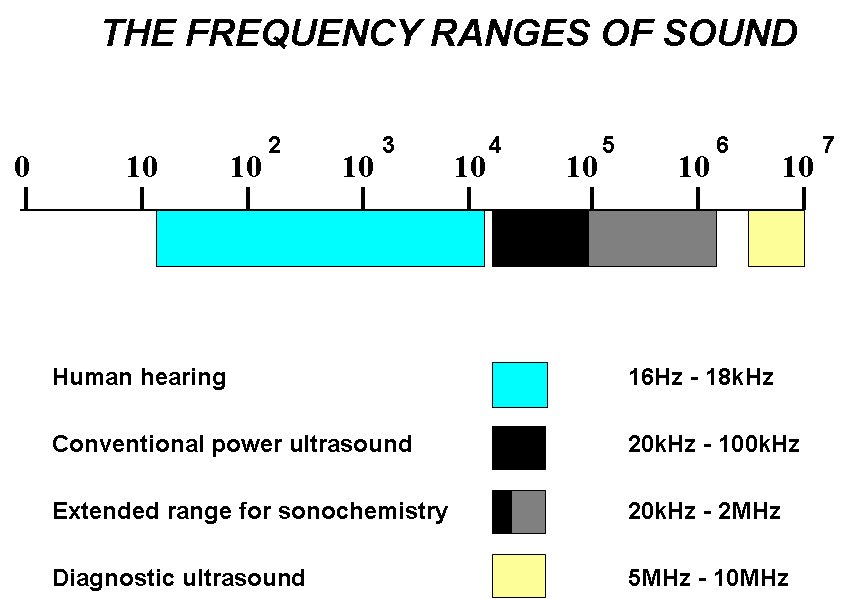

whistles) and bats use frequencies well above 50kHz for navigation (Figure 1.2).

Figure

1.2: Frequency ranges of sound

The broad classification of ultrasound as sound above 20kHz and up to 100MHz can

be subdivided into two distinct regions Power and Diagnostic. The former is

generally at lower frequency end where greater acoustic energy can be generated

to induce cavitation in liquids, the origin of chemical effects. Sonochemistry

normally uses frequencies between 20 and 40kHz simply because this is the range

employed in common laboratory equipment. However since acoustic cavitation in

liquids can be generated well above these frequencies, recent researches into

sonochemistry use a much broader range (Figure 1.2). High frequency ultrasound

from around 5MHz and above does not produce cavitation and this is the range

used in medical imaging.

A whistle which generates a frequency 20kHz is inaudible to humans but perfectly

audible to a dog - and produces no physical harm to either. It is however in the

correct FREQUENCY range to affect chemical reactivity (Power Ultrasound). Yet

such a whistle blown in a laboratory will not influence chemical reactions in

any way. This is because the whistle is producing sound energy in air and

airborne sound cannot be transferred into a liquid.

1.3 REFERENCES

1. A.P.Cracknell, Ultrasonics,

Chapter 6, pp 92-105 (1980) Wykenham Publishers

2. J.Curie and P.Curie, Compt.

Rend. (1880) 91, 294.

3. J.Curie and P.Curie, Compt.

Rend. (1881) 93, 1137.

4. F.Galton, Inquiries into

human faculty and development (1883) MacMillan, London.

5. J.Thornycroft and S.W.Barnaby,

"Torpedo boat destroyers", Proc.Inst.Civil.Engineers (1895) 122, 51

2. ACOUSTIC CAVITATION

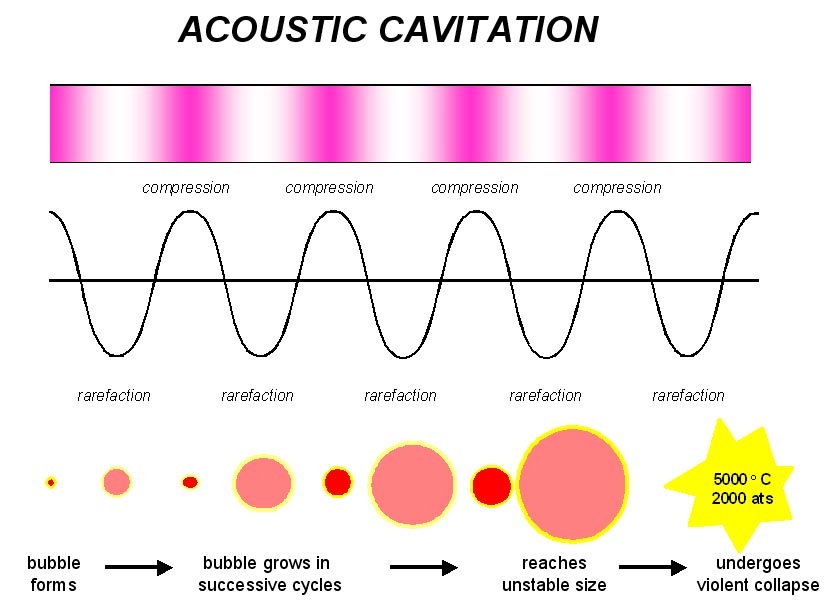

Power ultrasound enhances chemical and physical changes in a liquid medium

through the generation and subsequent destruction of cavitation bubbles. Like

any sound wave ultrasound is propagated via a series of compression and

rarefaction waves induced in the molecules of the medium through which it

passes. At sufficiently high power the rarefaction cycle may exceed the

attractive forces of the molecules of the liquid and cavitation bubbles will

form. Such bubbles grow by a process known as rectified diffusion i.e. small

amounts of vapour (or gas) from the medium enters the bubble during its

expansion phase and is not fully expelled during compression. The bubbles grow

over the period of a few cycles to an equilibrium size for the particular

frequency applied. It is the fate of these bubbles when they collapse in

succeeding compression cycles which generates the energy for chemical and

mechanical effects (Figure 2.1). Cavitation bubble collapse is a remarkable

phenomenon induced throughout the liquid by the power of sound. In aqueous

systems at an ultrasonic frequency of 20kHz each cavitation bubble collapse acts

as a localised "hotspot" generating temperatures of about 4,000 K and pressures

in excess of 1000 atmospheres [1-3].

Figure 2.1: Generation of an acoustic bubble

The cavitation bubble has a variety of effects within the liquid medium

depending upon the type of system in which it is generated. These systems can be

broadly divided into homogeneous liquid, heterogeneous solid/liquid and

heterogeneous liquid/liquid. Within chemical systems these three groupings

represent most processing situations.

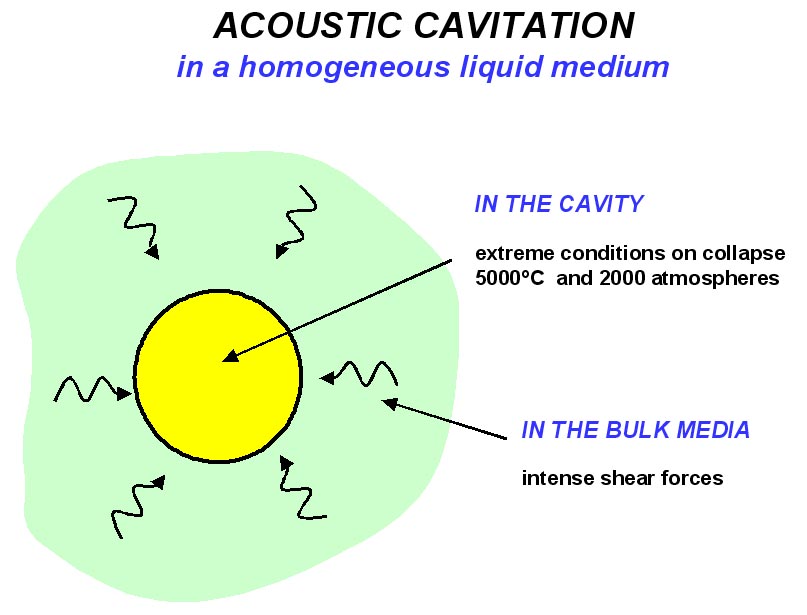

2.1 HOMOGENEOUS

LIQUID-PHASE REACTIONS

(i) in the bulk liquid immediately

surrounding the bubble where the rapid collapse of the bubble generates shear

forces which can produce mechanical effects and

(ii) in the bubble itself where any species introduced during its formation will

be subjected to extreme conditions of temperature and pressure on collapse

leading to chemical effects. (Figure 2.2).

Figure 2.2: Acoustic cavitation in a homogeneous liquid

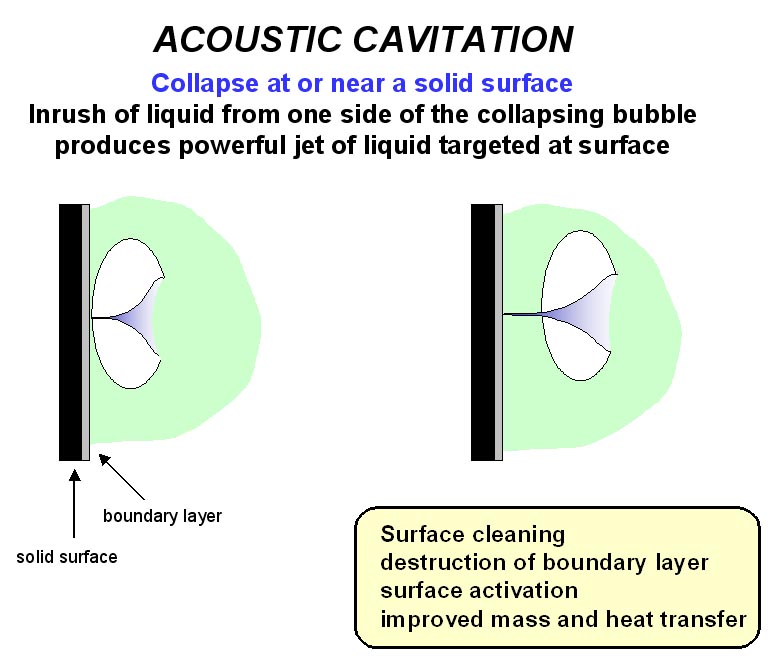

2.2 CAVITATION NEAR A SURFACE

Unlike cavitation bubble collapse in the bulk liquid, collapse of a cavitation

bubble on or near to a surface is unsymmetrical

because the surface provides resistance to liquid flow from that side. The

result is an inrush of liquid predominantly from the side of the bubble remote

from the surface resulting in a powerful liquid jet being formed, targeted at

the surface (Figure 2.3). The effect is equivalent to high pressure jetting and

is the reason that ultrasound is used for cleaning. This effect can also

activate solid catalysts and increase mass and heat transfer to the surface by

disruption of the interfacial boundary layers.

Figure 2.3: Cavitation bubble collapse at or near a solid surface

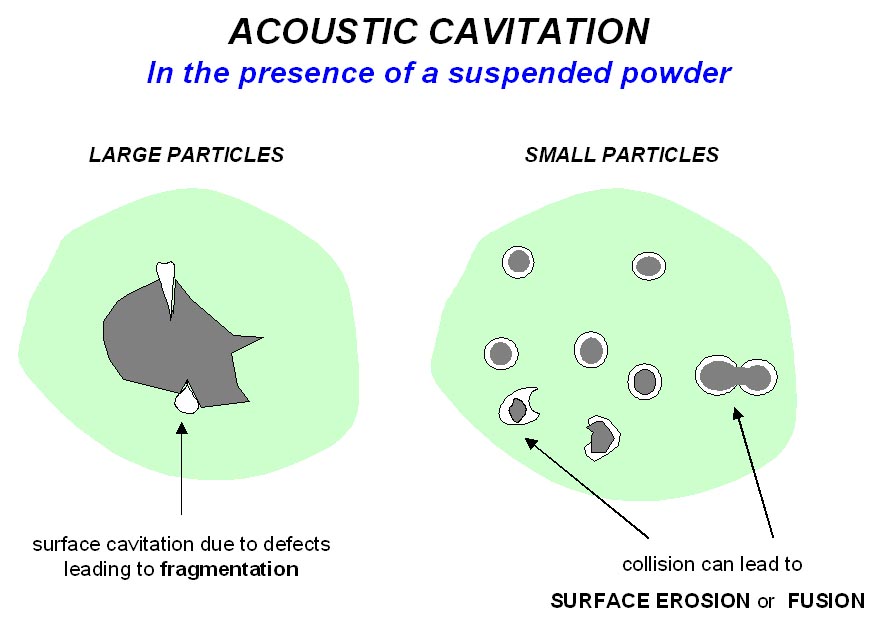

2.3 HETEROGEN EOUS

POWDER-LIQUID REACTIONS

EOUS

POWDER-LIQUID REACTIONS

Acoustic cavitation can

produce

dramatic effects on powders suspended in a liquid (Figure 2.4). Surface

imperfections or trapped gas can act as the nuclei for cavitation bubble

formation on the surface of a particle and subsequent surface collapse can then

lead to shock waves which break the particle apart. Cavitation bubble collapse

in the liquid phase near to a particle can force it into rapid motion. Under

these circumstances the general dispersive effect is accompanied by

interparticle collisions which can lead to erosion, surface cleaning and wetting

of the particles and particle size reduction.

Figure 2.4: Acoustic cavitation in a liquid with a suspended powder

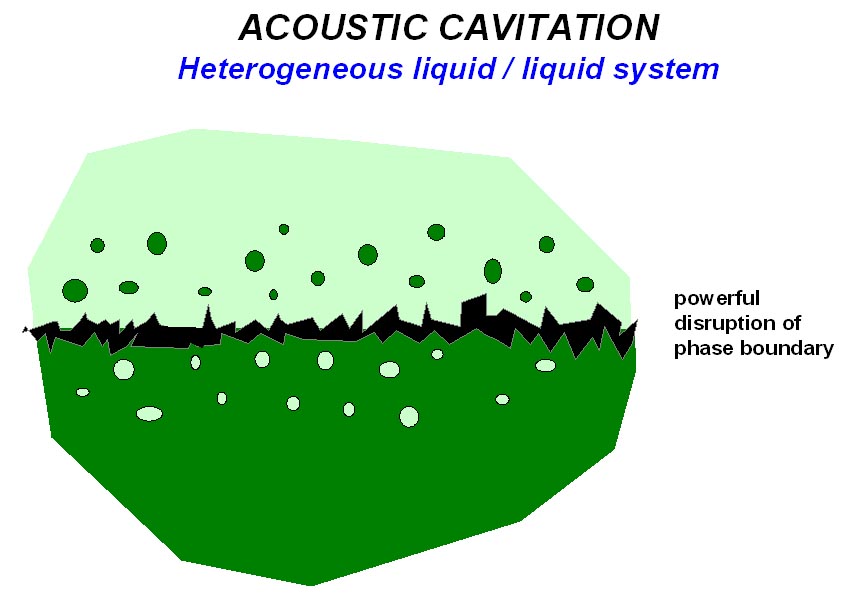

In heterogeneous liquid/liquid reactions, cavitational collapse at or near the

interface will cause disruption

and mixing, resulting in the formation of very fine emulsions (Figure 2.5).

Figure 2.5: Cavitation effects in a heterogeneous liquid/liquid system

2.4 REFERENCES FOR

CAVITATION

1. E.A.Neppiras, Ultrasonics

(1984) 22, 25.

2. A.Henglein, Ultrasonics

(1987) 25, 6.

3. K.S.Suslick, Science (1990)

247, 1439.

3. TRANSDUCERS

A transducer is the name for a device capable of converting one form of energy

into another, a simple example being a loudspeaker which converts electrical

energy to sound energy. Ultrasonic transducers are designed to convert either

mechanical or electrical energy into high frequency sound and there are three

main types: gas driven, liquid driven and electromechanical.

3.1

GAS-D RIVEN

TRANSDUCERS

RIVEN

TRANSDUCERS

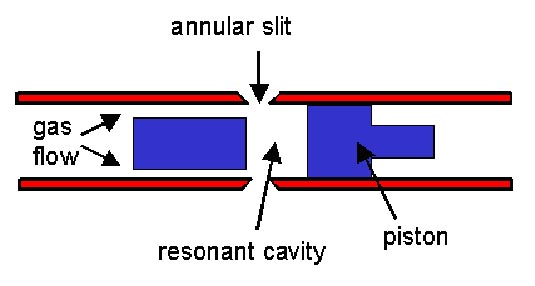

These are, quite

simply, whistles

with high frequency output (the dog whistle is a

familiar example). The history of the generation of ultrasound via whistles

dates back

100 years to the work of F.Galton who was interested in establishing the

threshold levels of human hearing. He produced a whistle that generated sound of

known frequencies and was able to determine that the normal limit of human

hearing is around 18kHz. Galton's whistle was constructed from a brass tube with

an internal diameter of about two millimetres (Figure 3.1) and operated by

passing a jet of gas through an orifice into a resonating cavity. On moving the

plunger the size of the cavity could be changed to alter the "pitch" or

frequency of the sound emitted. An adaptation of this early principle is to be

found in some dog whistles that have adjustable pitch.

Figure 3.1: Galton Whistle

An alternative form of gas generated ultrasound is the siren. When a solid

object is passed rapidly back-and-forth across a jet of high pressure gas it

interferes with the gas flow and produces sound of the same frequency at which

the flow is disturbed. A siren can be designed by arranging that the nozzle of a

gas jet impinges on the inner surface of a cylinder through which there are a

series of regularly spaced perforations. When the cylinder is rotated the jet of

gas emerging from the nozzle will rapidly alternate between facing a hole or the

solid surface. The pitch of the sound generated by this device

will depend upon the speed of rotation of the cylinder. Neither type of

transducer has any significant chemical application since the efficient transfer

of acoustic energy from a gas to a liquid is not possible. However whistles are

used for the atomization of liquids.

The conventional method of producing an atomized spray from a liquid is to force

it at high velocity through a small aperture. (A typical domestic examples being

a spray mist bottle for

perfume). The disadvantage in the design of conventional equipment is that the

requirement for a high liquid velocity and a small orifice restricts its usage

to low viscosity liquids and these atomizers are often subject to blockage at

the orifice.

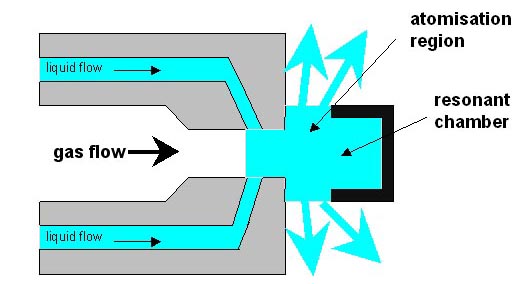

Figure 3.2 shows a schematic gas driven atomizer. The system comprises of an air

or gas jet, which is forced into an orifice where it expands and produces a

shock wave. The result is an intense field of sonic energy focused between the

nozzle body and the resonator gap. When liquid is introduced into this region it

is vigorously sheared into droplets by the acoustic field. Air by-passing the

resonator carries the atomized droplets downstream in a fine soft plume shaped

spray. The droplets produced are small and have a low forward velocity. Atomized

water sprays have many uses

including dust suppression in industry and humidifiers for horticultural use

under glass.

Figure 3.2: Gas Driven Atomizer

3.2

LIQUID-DRIVEN TRANSDUCERS

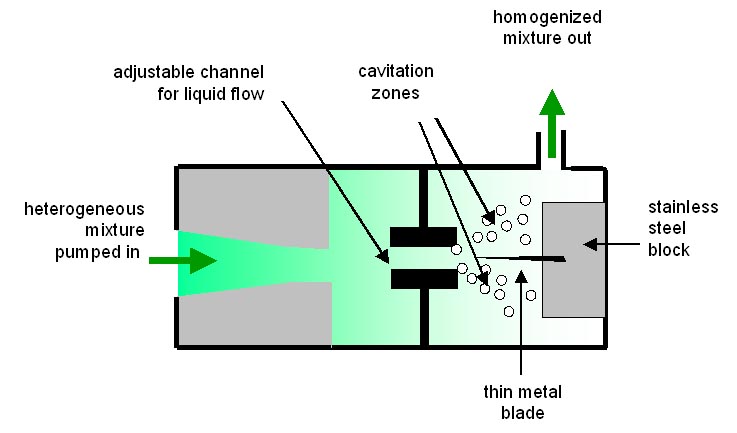

In essence this type of transducer is a "liquid whistle" and generates

cavitation via the motion of a liquid rather

than a gas. Process material is forced at high velocity by the homogeniser pump

through a special orifice from which it emerges as a jet which impacts

upon a steel blade (Figure 3.3). There are two ways in which cavitational mixing

can occur at this point. Firstly through the Venturi effect as the liquid

rapidly expands into a larger volume on exiting the orifice and secondly via the

blade which is caused to vibrate by the process material flowing over it. The

relationship between orifice and blade is critically controlled to optimise

blade activity. The required operating pressure and throughput is determined by

the use of different sizes and shapes of the orifices and the velocity can be

changed to achieve the necessary particle size or degree of dispersion. With no

moving parts, other than a pump, the system is rugged and durable. When a

mixture of immiscible liquids is forced through the orifice and across the blade

cavitational mixing produces extremely efficient homogenization.

Figure

3.3: Liquid Whistle

3.3

ELECTROMECHANICAL TRANSDUCERS

The two main types of electromechanical transducers are based on either the

piezoelectric or the magnetostrictive effect. The most commonly used of which

are piezoelectric transducers, generally employed to power the bath and probe

type sonicator systems. Although more expensive than mechanical transducers,

electromechanical

transducers are by far the most versatile.

3.3.1

Magnetostrictive Tr ansducers

ansducers

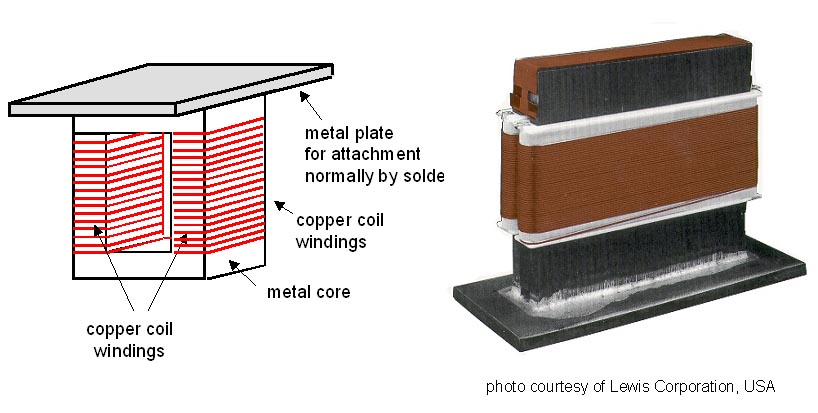

Historically magnetostrictive transducers were the first to be used on an

industrial scale to generate high power ultrasound. These are devices which use

an effect found in some materials e.g. nickel which reduce in size when placed

in a magnetic field and return to normal dimensions when the field is removed (magnetostriction).

When the magnetic field is applied as a series of short pulses to a

magnetostrictive material it vibrates at the same frequency. In simple terms

such a transducer can be thought of as a solenoid in which the magnetostrictive

material (normally a laminated metal or alloy) forms the core with copper wire

winding. To avoid magnetic losses two such solenoids are wound and connected in

a loop (Figure 3.4).

Figure 3.4: Piezoelectric Sandwich Transducer

The major advantages of magnetostrictive systems are that they are of an

extremely robust and durable construction and provide very large driving forces.

This makes them an attractive proposition for heavy duty industrial processing.

There are however two disadvantages, firstly the upper limit to the frequency

range is 100kHz, beyond which the metal cannot respond fast enough to the

magnetostrictive effect, and secondly the electrical efficiency is less than 60%

with significant losses emerging as heat. As a result of the second of these

problems all magnetostrictive transducers subject to extended use are liquid

cooled. This has meant that piezoelectric transducers (see below) which are more

efficient and operate over a wider frequency range are generally considered to

be the better choice in sonochemistry, especially in laboratory situations.

However now that a range of industrial applications for sonochemistry are under

consideration, particularly those requiring heavy duty continuous usage at high

operating temperatures, the magnetostrictive transducer is coming back into

consideration.

Many improvements in the operating efficiency of this type of transducer have

been made all of which are based on finding a more efficient magnetostrictive

core. The original nickel based alloys have been replaced by more electrically

efficient cobalt/iron combinations and, more recently, aluminium/iron with a

small amount of chromium. One of the latest developments in magnetostrictive

technology has been the introduction of a new material called TERFINOL-D. This

is an alloy of the rare earths terbium and dysprosium with iron which is zone

refined to produce a material almost in the form of a single crystal. It can be

produced in various forms, rods, laminates, tubes etc and has several major

advantages over the more conventional alloys used. A magnetostrictive transducer

based on this material can generate more power than a conventional piezoelectric

transducer, it is compact (about 50% smaller) and lighter than other

magnetostrictives. It does have the same problem as other such devices in that

it has an upper limit of frequency response - in this case 70kHz.

3.3.2

Piezoelectric Transducers

The most common types of transducer used for both the generation and detection

of ultrasound employ materials that exhibit the piezoelectric effect, discovered

over a century ago. Such materials have the following two complementary

properties:

1.

The direct effect -

when pressure is applied across the large surfaces of the section a charge is

generated on each face equal in size but of opposite sign. This polarity is

reversed if tension is applied across the surfaces.

2.

The inverse effect - if a charge is applied to one face of the section

and an equal but opposite charge to the other face then the whole section of

crystal will either expand or contract depending on the polarity of the applied

charges. Thus on applying rapidly reversing charges to a piezoelectric material

fluctuations in dimensions will be produced. This effect can be harnessed to

transmit ultrasonic vibrations from the crystal section through whatever medium

with which it is in contact.

Quartz was the piezoelectric material originally used in devices such as the

very early types of ASDIC underwater ranging equipment. Quartz is not a particularly good material for

this purpose because of its mechanical properties, it is a somewhat fragile and

difficult to machine. Modern transducers are based on ceramics containing

piezoelectric materials These materials cannot be obtained as large single

crystals and so, instead, they are ground with binders and sintered under

pressure at above 1000oC to form a ceramic. Cooling from above their

ferroelectric transition temperature in a magnetic field then aligns the

crystallites of the ceramic. Such transducers can be produced in different

shapes and sizes. Nowadays the most frequently employed piezoceramic contains

lead zirconate titanate (commonly referred to as PZT where the P represents

plumbum - the chemical term for the element lead - and the Z and T are initials

from the name of the salts).

underwater ranging equipment. Quartz is not a particularly good material for

this purpose because of its mechanical properties, it is a somewhat fragile and

difficult to machine. Modern transducers are based on ceramics containing

piezoelectric materials These materials cannot be obtained as large single

crystals and so, instead, they are ground with binders and sintered under

pressure at above 1000oC to form a ceramic. Cooling from above their

ferroelectric transition temperature in a magnetic field then aligns the

crystallites of the ceramic. Such transducers can be produced in different

shapes and sizes. Nowadays the most frequently employed piezoceramic contains

lead zirconate titanate (commonly referred to as PZT where the P represents

plumbum - the chemical term for the element lead - and the Z and T are initials

from the name of the salts).

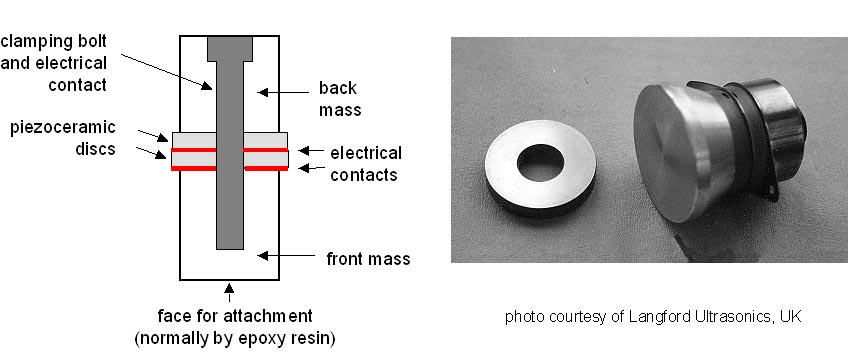

Figure 3.5: Piezo electric Transducer

The most common form is a disk with a central hole. In a power transducer it is

normal practise to clamp two of these piezoelectric disks between metal blocks

which serve both to protect the delicate crystalline material and to prevent it

from overheating by acting as a heat sink. The resulting "sandwich" provides a

durable unit with doubled mechanical effect (Figure 3.5). The unit is generally

one half wavelength long (although multiples of this can be used). The peak to

peak amplitudes generated by such systems are normally of the order of l0-20

microns and they are electrically efficient. Generally piezoelectric devices

must be cooled if they are to be used for long periods at high temperatures

because the ceramic material will degrade under these conditions.

Such transducers are highly efficient (>95%) and, depending on dimensions, can

be used over the whole range of ultrasonic frequencies from 20kHz to many MHz.

They are the exclusive choice in medical scanning which uses frequencies above

5MHz.

4. REACTOR DESIGN AND SCALE UP

The design of

sonochemical reactors and the rationale for the scale up of successful

laboratory ultrasonic experiments are clear goals in sonochemistry and

sonoprocessing. Indeed the progress of sonochemistry in green and

sustainable chemistry is dependent upon the possibility of scaling up the

excellent laboratory results for industrial use. The first step in the

progression of a sonochemical process from laboratory to large scale is to

determine whether the ultrasonic enhancement is the result of a mechanical or a

truly chemical effect. If it is mechanical then ultrasonic pre‑treatment of

slurry may be all that is required before the reacting system is subjected to a

subsequent conventional type reaction. If the effect is truly sonochemical

however then sonication must be provided during the reaction itself. The second

decision to be made is whether the reactor should be of the batch or flow type.

Whichever type is to be used there are only three basic ways in which ultrasonic

energy can be introduced to the reacting medium.

·

Immerse

reactor in a tank of sonicated liquid (e.g. flask dipped into a cleaning

bath)

·

Immerse an

ultrasonic source directly into the reaction medium (e.g. probe placed in a

reaction vessel)

·

Use

reactor constructed with vibrating walls (e.g. a tube operating through

radial vibrations)

4.1 Batch

Treatment

The obvious batch treatment processor is the ultrasonic cleaning

bath which is a readily available source of low intensity ultrasonic irradiation

generally at a frequency of around 40kHz. A reactor based on this design might

require adaptation to provide chemically resistant walls, a sealed lid for work

under an inert atmosphere and mechanical stirring. Using this system for large

volume treatment the acoustic energy entering the reaction would be quite small

and any stirrer and fittings in the bath would cause attenuation of the sound

energy.

An alternative configuration would involve using a submersible

transducer assembly which have been used for many years in the cleaning

industry. It consists of a sealed unit within which transducers are bonded to

the inside of one face and can be designed to fit into any existing reaction

vessel.

4.2 Flow

Systems

Flow Systems are generally regarded as the best approach to

industrial scale sonochemistry. The general arrangement would consist of a flow

loop outside a normal batch reactor which acts as a reservoir within which

conventional chemistry can occur. Such an arrangement allows the ultrasonic dose

of energy entering the reaction to be controlled by transducer power input and

flow rate (residence time). Temperature control is achieved through heat

exchange in the circulating reaction mixture.

Pipes of various

cross‑sectional geometry can be converted to flow processors by generating

ultrasonic vibrations through their walls. The length of pipe must be accurately

designed so that a null point exists at each end and it can then be retro‑fitted

to existing pipework. Such systems are capable of handling high flow rates and

viscous materials. There are four common cross-sectional geometries:

rectangular, pentagonal, hexagonal and circular. The pentagonal pipe provides a

fairly uniform ultrasonic field since the energy from each irradiating face is

reflected at an angle from the two opposite faces. The other configurations

provide a "focus" of energy in the centre where direct energy and that reflected

from the opposite wall meet.

4.3 References

1

Practical

Considerations for Process Optimisation,

by T.J.Mason and E.Cordemans de Meulenaer, Synthetic Organic Sonochemistry,

ed J-L.Luche, Plenum Press, 301-328 (1998).

2

The design of

ultrasonic reactors for environmental remediation,

T J Mason, Advances in Sonochemistry, 6,

Ultrasound in Environmental Protection, ed. T.J.Mason and A.Tiehm, Elsevier,

247-268 (2001).

3

High

Powered Ultrasound in Physical and Chemical Processing,

T.J.Mason, New Acoustics – Selected Topics, eds C.Ranz-Guerra and

J.A.Gallego-Juarez, Biblioteca de Ciecias, 7, Consejo Superior de

Investigaciones Cientificas, 105-138, (2003).

4

A novel angular

geometry for the sonochemical silver recovery process at cylinder electrodes,

B.G. Pollet, J.P. Lorimer, S.S. Phull, T.J. Mason and J.-Y. Hihn,

Ultrasonics Sonochemistry

10, pp 217-222

(2003).

5. EXAMPLES OF RESEARCH PROJECTS

“Prospects for

scale-up in the ultrasonic extraction of natural materials”

“Large scale sonochemical processing”

“Ultrasonic intensification of chemical processing and related

operations”

“Sonic and ultrasonic removal of

chemical contaminants from soil in the laboratory and on a large scale”